Vehicle temperature monitoring

cold chain distribution

Don't Let Damaged Stock Sink Your Profits

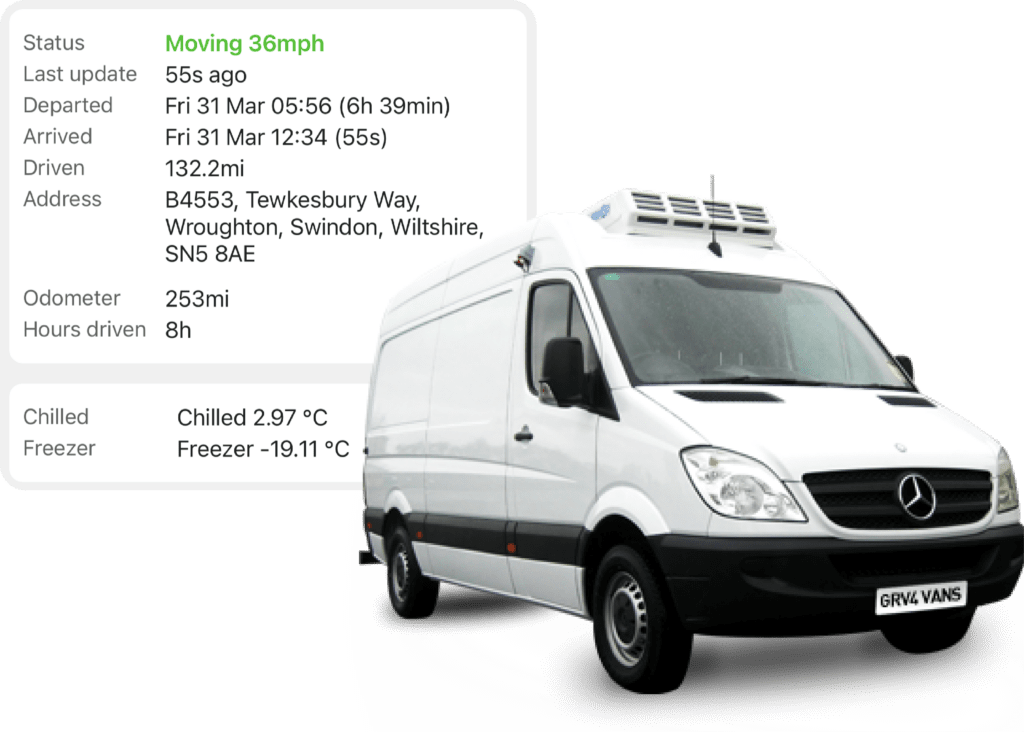

Fleet Witness vehicle tracking supports businesses that require uninterrupted refrigerated goods distribution, such as food suppliers and vaccine couriers. Temperature probes installed in refrigerated or frozen vehicles continuously transmit temperature readings to the GPS tracking device. This data is then sent directly to your vehicle tracking system, along with comprehensive information about the vehicle’s movements, giving you a complete overview of your fleet operations.

Fleet Witness Cold Chain helps you

Support all your vehicles

Gain the advantage of customisable temperature data, all accessible through a single, easy-to-use platform.

Be compliant

Receive automated email or in-app alerts if temperatures stray outside of preset parameters.

Open door alerts

Receive instant alerts when vehicle doors aren’t closed², helping protect cargo and maintain temperature control.

Journey reports

Pinpoint the exact location of temperature events to bring transparency to your cold chain operations.

Track Temperature Events with Precision Using Fleet Witness

Fleet Witness offers real-time temperature monitoring alerts to help you respond instantly to critical temperature breaches. Set fully configurable sensor thresholds¹ to match your cargo’s specific requirements—whether for cold chain compliance, perishables, or pharmaceuticals. Stay in control of your fleet’s temperature-sensitive logistics at all times.

Real-Time Temperature Alerts with Fleet Witness

Fleet Witness pinpoints the exact location of every temperature event, giving you full visibility into cold chain operations. With detailed temperature logs and map trace views, you can monitor changes throughout the journey and assess whether cargo quality has been affected. Understanding temperature variations in transit is essential for maintaining product integrity on arrival.

Real-Time Temperature Alerts with Fleet Witness

Fleet Witness uses digital inputs to display real-time door status (OPEN/CLOSE)² and cooling unit activity (ON/OFF), helping you respond swiftly to potential cold chain breaches. An open door or inactive cooling system can lead to temperature fluctuations that risk compromising cargo quality. Stay informed and protect your goods in transit.

Our latest updates, blogs & industry insights

News & events

Resource Centre

Browse our latest blog posts, helpful guides, videos, and expert opinions on a variety of industry-related topics.

Case Studies

Check out our case studies and discover how we’re helping fleets improve the way they manage drivers and vehicles.

Resellers & Careers

Whether you want to resell our solutions, integrate with our platform, or join our growing team — we’d love to connect.

Frequently Asked Question

The cold chain is a temperature controlled supply chain that maintains required conditions from production to final delivery. Each stage, including manufacturing, storage, distribution and retail, must be carefully managed to protect the quality of temperature sensitive goods.

Examples of cold chain products include vaccines, pharmaceuticals, chemicals and perishable food such as meat, fish and dairy. The process begins at the factory or farm, moves through storage facilities, and continues with refrigerated transport to the final destination.

Refrigerated fleets play an essential role in protecting product quality and ensuring full cold chain compliance throughout the journey.

All goods moved within the cold chain are temperature sensitive. Examples include food, medicine, vaccines, chemicals, plants and medical equipment. These products must be transported within specific temperature ranges to maintain their safety, quality and effectiveness.

The main benefit of cold chain management is protecting the integrity of the cargo. Incorrect temperatures during transport can result in damaged or rejected goods, financial losses and dissatisfied customers. In some cases, temperature failures may even pose risks to human health. Effective cold chain management helps fleets avoid compliance issues and protect their reputation.

Cold chain transport involves maintaining specific temperature ranges based on the type of cargo. Fleets must ensure that the correct range is preserved for each product category. For example, frozen goods are generally kept between minus 18 degrees Celsius and minus 20 degrees Celsius.

Temperature regulations can vary by region and are influenced by factors such as climate, industry standards and local regulatory bodies. Organisations such as the European Pharmacopoeia and the World Health Organization define standard temperature categories:

Deep freeze: below minus 15 degrees Celsius

Refrigerator: 2 to 8 degrees Celsius

Cold: 8 to 15 degrees Celsius

Room temperature: 15 to 25 degrees Celsius

These ranges are critical for correct product storage and safe transport. Fleets must stay informed and compliant with the latest temperature requirements in the regions where they operate.

Disclaimer:

1.Configurable sensor thresholds must remain within the operational temperature range of -20 °C to +60 °C (−4 °F to +140 °F). Sensors must also be within 80 metres of a compatible Fleet Witness tracker to ensure accurate data transmission.

2.Door status data via CAN-BUS requires integration with the vehicle’s CAN system. This feature is only available for vehicles on the Fleet Witness compatible vehicle list. Please check compatibility before installation.